Commercial Vacuum Pump, Size And Style Support Custom, Price For Reference Only

2022-11-08

Vacuum pump refers to the device or equipment that uses mechanical, physical, chemical or physicochemical methods to extract air from the evacuated container to obtain vacuum. Generally speaking, vacuum pump is a device that uses various methods to improve, generate and maintain vacuum in a closed space.

According to the working principle of vacuum pump, vacuum pump can be basically divided into two types, namely gas capture pump and gas transfer pump. It is widely used in metallurgy, chemical industry, food, electronic coating and other industries.

(1) Overall structure type of pump

The overall structure of the vacuum pump is determined by the layout of the pump body.

The air inlet and outlet of the vertical structure are horizontally arranged, and it is convenient to assemble and connect the pipeline. However, the center of gravity of the pump is high and the stability is poor when running at high speed, so this type is mostly used for small pumps.

The air inlet of the horizontal pump is at the top and the air outlet is at the bottom. Sometimes, for the convenience of installation and connection of vacuum system pipes, the exhaust port can be connected from the horizontal direction, that is, the inlet and exhaust directions are perpendicular to each other. At this time, the exhaust port can be opened from the left or right directions. In addition to one end of the exhaust pipe, the other end is blocked or connected to the bypass valve. The pump has low center of gravity and good stability at high speed. This structure is commonly used for large and medium-sized pumps.

The two rotor shafts of the pump are installed vertically with the horizontal plane. The assembly clearance of this structure is easy to control, the rotor assembly is convenient, and the pump occupies a small area. However, the center of gravity of the pump is relatively high, the gear is inconvenient to disassemble and assemble, and the lubricating mechanism is relatively complex.

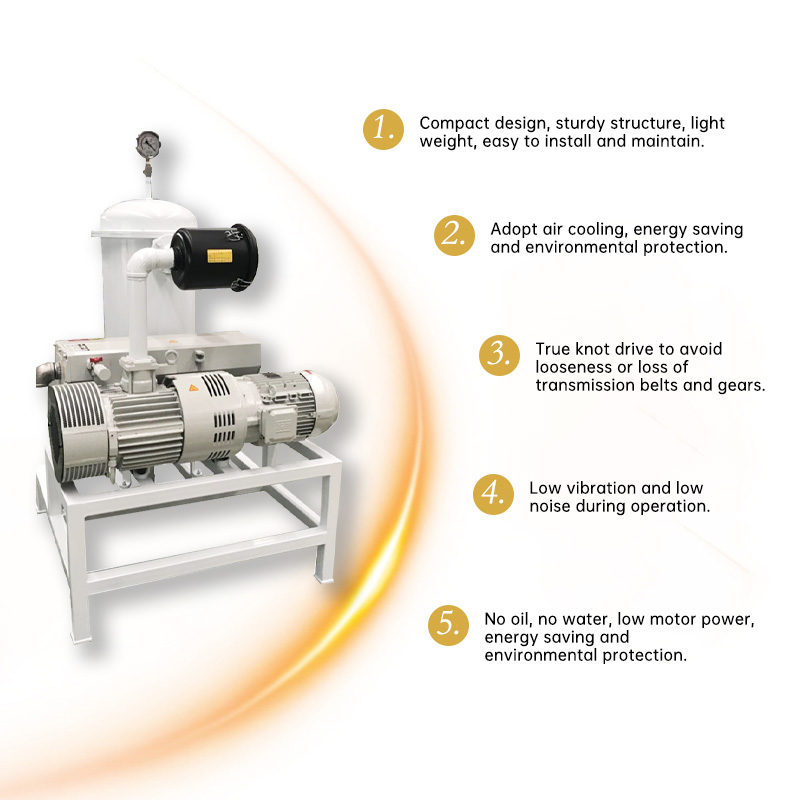

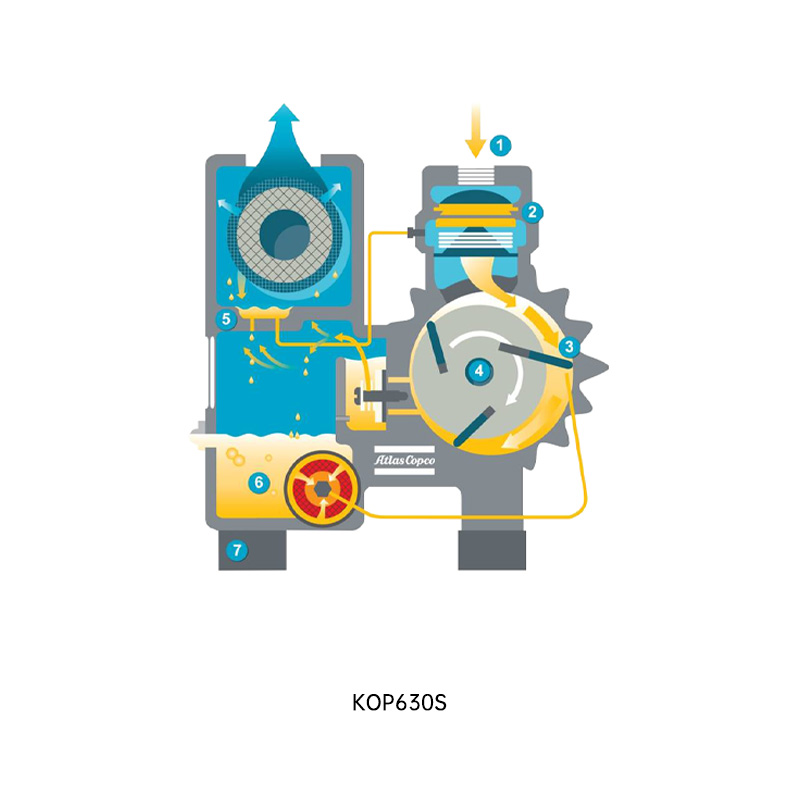

(2) Pump transmission mode

The two rotors of the vacuum pump operate synchronously through a pair of high-precision gears. The driving shaft is connected with the motor through a coupling. There are mainly two types of transmission structure: one is that the motor and gear are placed on the same side of the rotor, as shown in the figure. The driven rotor is directly driven by the motor end gear. In this way, the torsional deformation of the driving rotor shaft is small, and the clearance between the two rotors will not change due to the large torsional deformation of the driving shaft, so that the clearance between the rotors is uniform during operation. The biggest disadvantages of this transmission mode are: a There are three bearings on the driving shaft, which increases the difficulty of processing and assembling the pump, and it is inconvenient to disassemble and adjust the gear; b. The overall structure is not symmetrical, and the center of gravity of the pump is biased to one side of the motor and gearbox.

(1) Whether the vibration generated during the operation of the vacuum pump affects the process and environment. If the process is not allowed, the pump without vibration shall be selected or anti vibration measures shall be taken.

(2) Understand the composition of the extracted gas, whether the gas contains condensable steam, whether there is particulate dust, corrosivity, etc. When selecting a vacuum pump, it is necessary to know the gas composition and select the corresponding pump for the pumped gas. If the gas contains steam, particles and corrosive gas, it should be considered to install auxiliary equipment on the air inlet pipeline of the pump, such as condenser, dust remover, etc.

(3) The vacuum pump shall be able to discharge all the gas produced in the process of vacuum equipment under its working pressure.

(4)Properly combine the vacuum pump. As the vacuum pump has selective air extraction, sometimes one pump cannot meet the air extraction requirements, and several pumps need to be combined to complement each other to meet the air extraction requirements. For example, the titanium sublimation pump has a high pumping speed for hydrogen, but cannot pump helium, while the three pole sputtering ion pump (or the two pole asymmetric cathode sputtering ion pump) has a certain pumping speed for argon. The combination of the two will make the vacuum device obtain a better vacuum degree. In addition, some vacuum pumps can not work under atmospheric pressure and need pre vacuum; The outlet pressure of some vacuum pumps is lower than atmospheric pressure, so the front pump is required, so the pumps need to be combined for use.

(5)Requirements of vacuum equipment on oil pollution. If the equipment is strictly required to be oil-free, various oil-free pumps should be selected, such as water ring pump, molecular sieve adsorption pump, sputtering ion pump, cryogenic pump, etc. If the requirements are not strict, oil pump can be selected, and some oil pollution prevention measures, such as adding cold trap, baffle, oil trap, can also meet the requirements of clean vacuum.

(6)Correctly select the working point of the vacuum pump. Each type of pump has a certain working pressure range, for example, the working pressure range of 2BV series water ring vacuum pump is 760mmHg~25mmHg (absolute pressure). Within such a wide pressure range, the pumping speed of the pump varies with the pressure (refer to the pump performance curve for detailed changes), and its stable working pressure range is 760-60mmHg. Therefore, the working point of the pump should be selected within this range, rather than allowing it to work at 25~30mmHg for a long time.

(7) How does the oil vapor discharged from the vacuum pump affect the environment. If the environment is not allowed to be polluted, an oil-free vacuum pump can be selected, or the oil vapor can be discharged to the outside.

(8) The working pressure of the vacuum pump shall meet the requirements of the limit vacuum and working pressure of the vacuum equipment. For example, a vacuum drying process requires a working vacuum degree of 10 mmHg, and the limit vacuum degree of the selected vacuum pump should be at least 2 mmHg, preferably up to 1 mmHg. Generally, the limit vacuum degree of the pump shall be half to one order of magnitude higher than the working vacuum degree of the vacuum equipment.

NOFIT Building Materials Group Co., Ltd. is a modern comprehensive science and technology environmental protection enterprise integrating project design and development, equipment manufacturing, kiln engineering construction and technology output in four parts.

The company is the vice president unit of China Brick and Tile Association, the first to pass the two integration management system assessment, and has won the national high-tech enterprises, national intellectual property rights advantageous enterprises, Sichuan Province Enterprise Technology Center, the national AAA grade integrity enterprise and other honorary titles.

The company has national Grade B engineering design qualification, Grade 3 metallurgical construction general contracting qualification, 18 scientific researchers of intermediate level or above, and more than 190 technical and construction personnel of various types, with strong technical force, advanced processing equipment, and perfect after-sales service system, to provide high-quality products and comprehensive services for customers at home and abroad.

From R&D and production to after-sales service, the company always insists on scientific and environmental protection R&D concept and exquisite processing technology to shape a high quality kiln leader. Our R&D center provides users with engineering and process design for brick making production lines; machinery company provides complete sets of brick making equipment; robotics company provides professional intelligent robots and automation control systems; kiln company builds kilns and engineering construction for users; subordinate brick factories provide intuitive visualization services and provide users with personnel training, installation and commissioning services with rich production experience; technical service center provides plant construction The technical service center provides plant construction, renovation consulting, brick plant technology contracting and operation contracting services. We really realize the "one-stop"service of undertaking projects.

After several quenching, we finally cast a shining brand; a thousand hammers and refinements, forging a fine steel pencil. With strong research and development technology, excellent product quality and quality after-sales service, we will work hand in hand with friends from all walks of life at home and abroad to create the future together! In order to realize the science and technology, industrial prosperity, and continue to climb a new peak!

Weidong Ma

759280000@qq.com

YinBin Noffet Robot Manufacturing Store