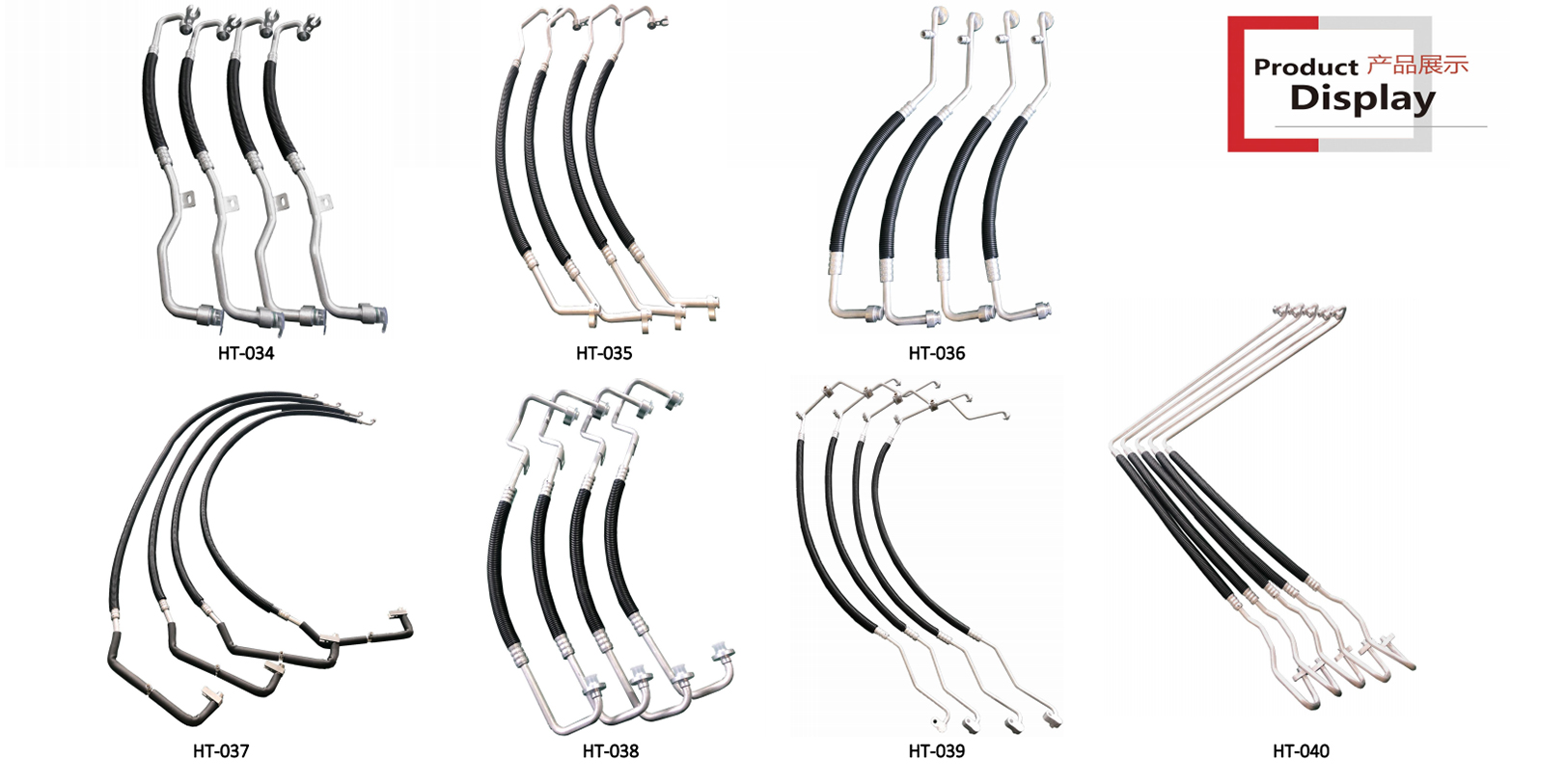

Auto Air Conditioning Pipeline

2022-11-03

The company is now cooperating with many large listed companies such as Chuanhuan Technology Co., Ltd., Shaanxi Jiahe Huaheng Thermal System Co., Ltd., Baoji Baojiacheng Automobile Air Conditioning Co., Ltd., and Shaanxi Automobile Group Commercial Vehicle Co., Ltd. Among them, the intelligent manufacturing of air-conditioning pipeline assembly and production equipment is an important project of the company. In addition, the company mainly produces metal pipeline products such as fuel system, cooling system, transmission system, braking system, etc., which are sold in Jinkangseres, Hezhong Automobile, Shaanxi Automobile, FAW, Changan, Geely, Zotye, SAIC-GM-Wuling, BYD, GAC, BAIC, Chunfeng and other major OEMs and motorcycle OEMs all over the country participated in the project. The company adheres to the concept of "details determine success or failure", pursues excellent quality, and provides customers with more efficient services.

Auto air conditioning pipeline is classified as high pressure pipe and low pressure pipe according to pressure. According to the classification of refrigeration state, it is gaseous tube and liquid tube. The composition of automobile air conditioning pipeline consists of: aluminum or steel pipe, joint (pressure plate, joint, nut, etc.), air conditioning hose, air conditioning bellows, aluminum sleeve, filling port, liquid sight glass, pressure switch, O-ring, plastic plug cap.

As each component assembly of auto air conditioning is generally installed in various parts of the car, the auto air conditioning pipeline connects these component assemblies to form a complete auto air conditioning system. If the compressor is the heart of the air conditioning system, the auto air conditioning pipeline is the blood vessel of the air conditioning system.

Sichuan Huitong Automobile Pipe Manufacturing Co., Ltd. was established in 2007. The company is mainly engaged in the supporting production of automobile aluminum pipes and automobile air-conditioning pipeline assemblies, as well as the intelligent manufacturing of production equipment. With independent development capabilities, the annual production capacity of 10 million pieces. Now we have our own mold development center, 3 automatic testing equipment, 5 automatic molding production lines, 1 automatic blanking machine, 3 automatic chamfering machines, 10 automatic pier head machines, and 1 automatic ultrasonic cleaning line. , 5 pipe bending machines, 2 intelligent assembly production lines.

With the care of people from all walks of life and the joint efforts of all employees, the company will continue to strive to surpass and pursue excellence.

Contact Person:Xinyu Zhu

Email:1476364530@qq.com htzz1688@gmail.com